Carbon Neutral

#NetZero

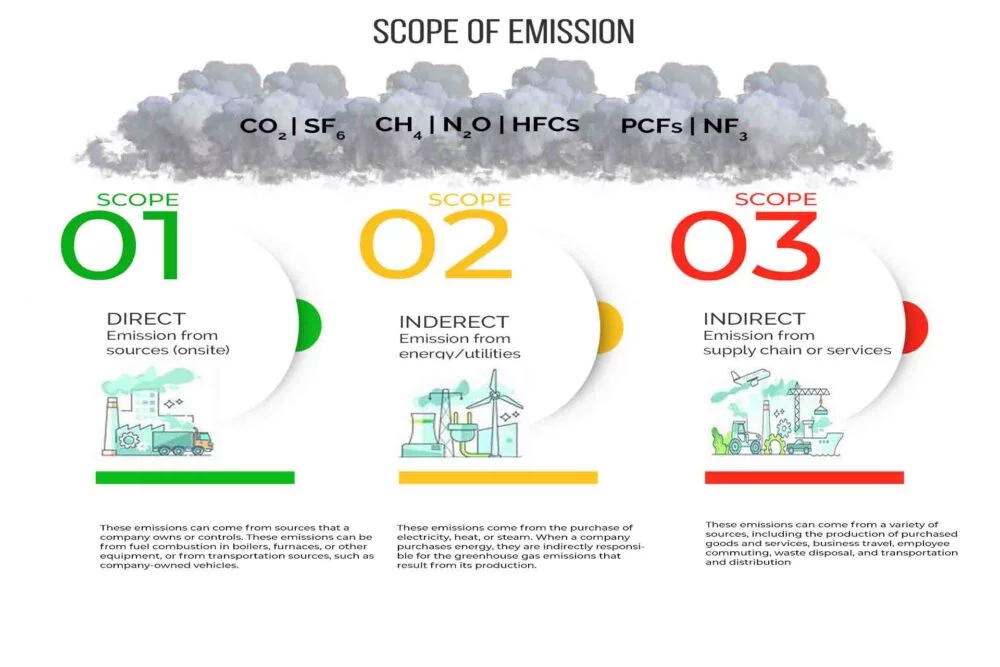

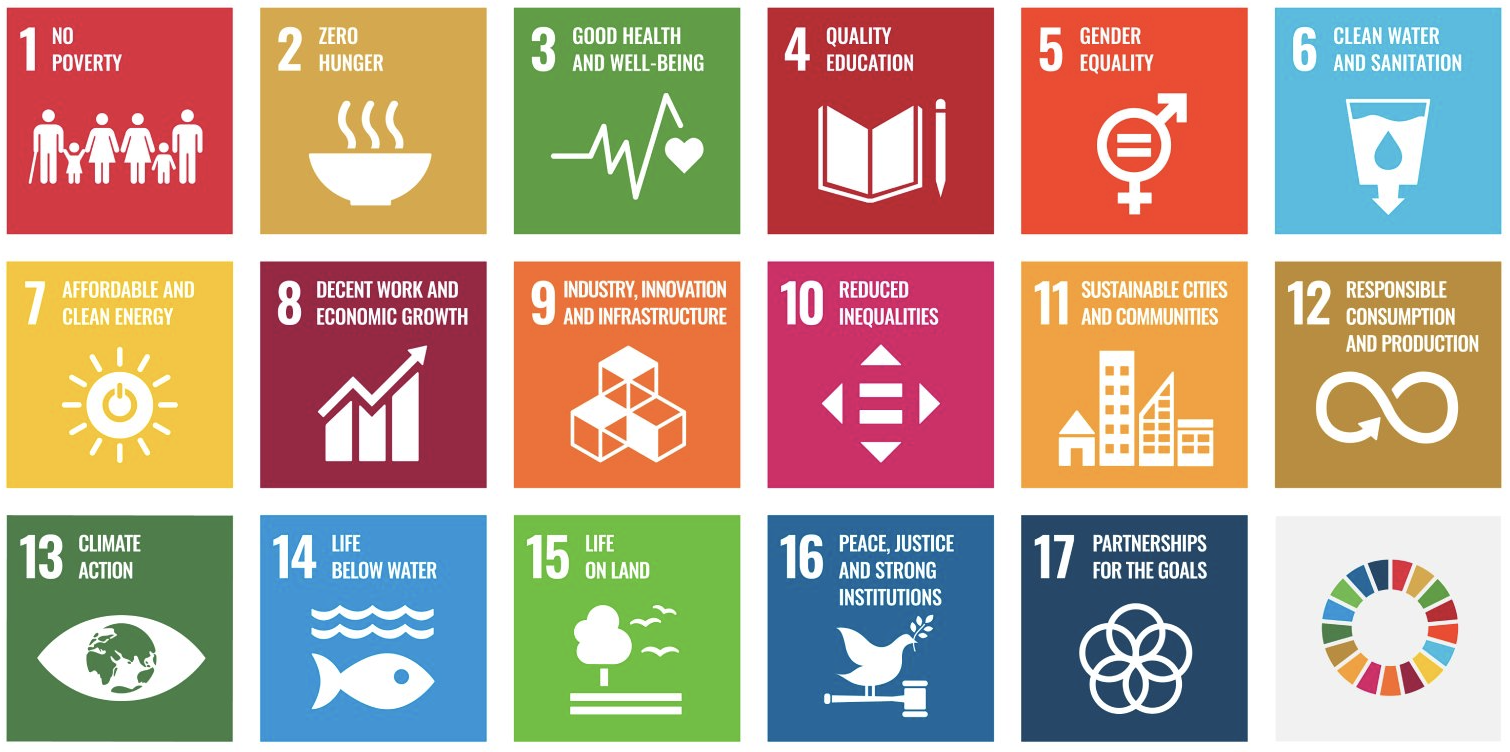

At Foodmaker, we are committed to meaningful climate action across our operations and supply chain.• Scope 1 & 2: We will achieve net zero emissions by December 2025. This covers all direct emissions from our owned operations and indirect emissions from purchased electricity and energy.

• Scope 3: We are targeting net zero by 2030 for all indirect emissions in our value chain, including those from raw materials, logistics, packaging, and downstream product use. This commitment reflects our strategy to build a more sustainable, transparent, and future-focused food system — while supporting our customers’ own environmental goals.

Picked with Purpose. Grown with Care.

#RawMaterials

At Foodmaker, we believe flavour should feel good — not just taste good. That’s why we team up with trusted suppliers and growers around the world to bring us the best herbs and spices, grown the right way.

Together, we make sure every ingredient is rooted in responsibility. As part of our Environmental & Social Assessment, we look for suppliers who:

• Support growers in creating safe, fair working conditions

• Champion planet-friendly farming that protects soil, water and all the buzzy little creatures

• Keep everything transparent — from seed to shelf

• Invest in local communities with tools, training and bright ideas

So, whether it’s a zingy rub or a punchy glaze, you’ll know it’s been made with more than just flavour in mind — it’s been made with fairness, responsibility, and a little bit of Foodmaker magic.

Carbon Miles

#Carbon

At Foodmaker, we believe in keeping things simple — and sustainable.

That’s why we work directly with trusted farmers and processors to create the shortest, most efficient supply chain possible.

By minimising the number of steps between the field and our factory, we reduce unnecessary handling, transport, and storage.

Fewer links in the chain means fewer carbon miles — and more transparency, freshness, and accountability every step of the way.

Purchasing

#Purchasing

Behind every blend is a supply chain you can trust. Our Purchasing Team ensures that every ingredient we source is safe, consistent, and responsibly managed.• Trusted supplier network — working with approved partners only

• Full compliance & traceability — aligned with BRCGS and retailer standards

• Cost management — securing value without compromising quality

• Market awareness — monitoring commodity trends and availability

• Sustainability focus — supporting recycling, waste reduction, and ethical sourcing

• Collaborative approach — working closely with NPD and operations to meet your brief

With the right partnerships and oversight, our Purchasing Team gives you confidence that every seasoning is built on quality, safety, and reliability.

Sustainable Building Design

#Building

Our facility is built with energy-saving features at its heart — designed to tread lightly on the planet while powering serious production.

Across all production areas, high-efficiency LED lighting keeps things bright while keeping our energy use low. These smart systems use up to 80% less electricity than traditional lighting and last significantly longer too, reducing both energy bills and waste.

We’ve started installing automated lighting controls that adjust brightness based on occupancy and natural light — helping us avoid lighting empty rooms and saving even more energy as we go. From floor to ceiling, we’ve made choices that prioritise sustainability without compromising on performance — proving that being green doesn’t mean slowing down.

Sustainability Starts with Our People

#People

At Foodmaker, we believe sustainability is a team effort — and it begins with how our staff get to work.

We actively support greener commuting through our Cycle to Work scheme and provide secure, covered bike parking to encourage pedal-powered travel.

For those using electric vehicles, we’ve installed charging points for both cars and bikes, making it easier for our team to make low-carbon choices every day. It’s all part of our commitment to building a culture of responsibility from the inside out.

Low-Energy Manufacturing Processes

#Manufacturing

At Foodmaker, sustainability is engineered into our daily operations. We optimise every step of production to reduce energy consumption while maintaining exceptional quality and safety.Our production methods are designed for efficiency — we minimised mix times that cut down on power usage and equipment wear.

Our manufacturing processes are controlled by intelligent PLC systems and variable-speed inverters, optimising operational speeds to enhance efficiency and reduce energy consumption.

We run on a 100% renewable gas (biogas) backed by RGGO certification energy tariff, meaning our electricity & gas is sourced exclusively from renewable providers.

Every recipe we blend is done with care — and a smaller environmental footprint.

Recycle Everything We Can

#Recycle

At Foodmaker, we’re passionate about reducing waste and recycling wherever possible.

All raw material packaging is carefully separated into paper and plastic then baled and sold on for reuse — turning waste into resource.

In the office we encourage sustainable habits using reusable water bottles, eliminating the need for disposable plastic or paper cups.

Where we can we have reduced the paper that we use throughout our process using our modern IT system to maintain logs.

Separate food waste collections became mandatory for most businesses from March 2025, but Foodmaker already delivers fully compliant food waste services. Our customers can continue business as usual, knowing their food waste is being managed responsibly and in line with current regulations.

From factory floor to meeting room, we’re making conscious choices to keep waste out of landfill and do our bit for a cleaner planet.

The Green Dream Sales Team

#ElectricCar

Our Sales Executives are leading the charge—literally.

Where we can we encourage members of the team to drive fully electric or hybrid vehicles, reducing emissions with every mile and supporting our mission for a cleaner, greener future.

But sustainability runs deeper than transport.

We use low-energy laptops and mobile devices, charge with smart power systems, and plan routes efficiently to cut down on unnecessary travel.

Wherever possible, we also switch the ignition off entirely—opting for Microsoft Teams meetings to connect remotely and lower our carbon footprint even further.

Whether it’s the road we travel or the way we work, we’re proving that flavour and responsibility can share the same journey.

Green Deliveries

#GreenTruck

We’re taking meaningful steps to make our deliveries greener.

By partnering with logistics carriers that offer electric or low-emission vehicle options, we’re actively reducing the environmental impact of our distribution.

Efficient route planning is at the core of our delivery model—ensuring minimal miles travelled per drop. Wherever possible, we consolidate orders to enable multi pallet drops per run, cutting down on both fuel use and carbon emissions.

It’s smarter, cleaner logistics—bringing flavour to your door with a lighter footprint on the planet.

Our Policies

#Policies

• Modern Slavery Statement - full compliance, including risk assessments of all suppliers• Supplier Code of Conduct - requiring ethical labour practices, fair wages, and safe working conditions

• No Child Labour Policy - zero tolerance for child exploitation in any part of the supply chain

• Fair Sourcing - prioritising suppliers who share our values on labour rights, ethics, and transparency

• Traceability Systems - ensuring full visibility from source to shipment, especially for high-risk commodities

• Regular Audits - on-site and desk-based audits of both UK and international suppliers

• Staff Training - educating our team on recognising risks of modern slavery and human rights violations

• Anonymous Reporting Channels - enabling whistleblowing without fear of reprisal

• Gender Equality and Inclusivity - supporting diverse hiring, pay parity, and inclusive workplace practices

• Ethical Certification Support - suppliers with SEDEX, Fairtrade, Rainforest Alliance, or B Corp credentials